Introduction to How a Car Engine Works A Comprehensive Guide

A car engine is a vital component of any vehicle, serving as its heart and soul. It is responsible for converting fuel into mechanical energy, which powers the automobile and propels it down the road. Understanding how a car engine works is essential not only for automotive enthusiasts but also for everyday drivers who rely on their vehicles for daily transportation. Familiarity with engine mechanics can enhance one’s ability to maintain the car, recognize potential issues, and improve fuel efficiency.

The significance of the engine in vehicle operation cannot be overstated. It works in conjunction with various other automotive systems, such as the transmission, exhaust, and cooling systems, to ensure seamless functionality. The engine operates on a cycle, typically converting chemical energy from fuel into kinetic energy through a series of controlled explosions. Throughout this process, air, fuel, and the ignition system play critical roles, collaborating to create the force necessary to move the vehicle. There are various types of engines, including internal combustion engines, which have been the traditional choice for cars, and newer electric engines that are gaining popularity in modern vehicles.

For individuals who wish to delve deeper into the mechanics of automotive technology, understanding how a car engine works is not only beneficial but also intriguing. This knowledge can empower car owners to make informed decisions regarding maintenance and repairs, potentially saving time and money. Furthermore, comprehension of engine functions can lead to greater appreciation for automotive engineering and the innovations that continue to shape the industry. From the complexities of the combustion process to the role of engine oils, understanding these fundamentals can provide both practical benefits and enhance the driving experience.

The Basic Components of a Car Engine

Understanding how a car engine works involves examining its fundamental components, each playing a pivotal role in the overall operation. The engine block serves as the core structure of the engine, housing various essential parts. It is typically made of cast iron or aluminum, balancing durability and weight, providing a sturdy base for the engine’s operation.

Within the engine block, the cylinders are formed, which are central to the combustion process. These cylindrical chambers contain the pistons, which move up and down as the engine operates. The pistons are tightly fitted to each cylinder and play a crucial role by compressing the air-fuel mixture within them, initiating combustion to produce power. This movement of pistons is converted into rotational motion by the crankshaft, which serves as a mechanism to transfer power to the drivetrain.

The camshaft works in tandem with the crankshaft, controlling the timing of the opening and closing of the engine’s valves. These valves are essential as they regulate the intake of air and fuel into the cylinders and the expulsion of exhaust gases. The precision of this operation ensures an efficient combustion cycle, which directly impacts the performance of the automotive engine.

Each of these components—the engine block, cylinders, pistons, crankshaft, camshaft, and valves—must operate in harmony for the engine to function effectively. When they work together, they generate the necessary power to propel vehicles, showcasing the intricate design of modern cars. Understanding these components reveals much about how a car engine works and highlights the significance of each part in the broader context of automotive engineering.

The Four-Stroke Cycle Explained

The operation of a car engine is primarily defined by the four-stroke cycle, a fundamental process that enhances the efficiency and performance of automotive engines. This cycle consists of four distinct phases: intake, compression, power, and exhaust. Understanding these stages is essential for grasping how a car engine works and how it provides power to the vehicle.

The first stroke, known as the intake stroke, initiates the cycle. During this phase, the intake valve opens, allowing a mixture of air and fuel to enter the combustion chamber as the piston moves down. This process is crucial because the appropriate mixture of fuel and air is vital for optimal combustion, which subsequently affects engine performance.

The second phase is the compression stroke. Once the piston has reached the bottom of its travel, the intake valve closes, and the piston moves back up to compress the air-fuel mixture. This compression increases the mixture’s temperature and pressure, making it more volatile and ready for combustion. A well-executed compression stroke directly influences the engine’s efficiency, contributing significantly to how a car engine works.

The third stroke, the power stroke, is where the actual transformation of energy occurs. At this point, the spark plug ignites the compressed air-fuel mixture, creating a controlled explosion that forces the piston down. This surge of energy is what drives the crankshaft, ultimately converting the engine’s power to the vehicle’s wheels, facilitating movement.

Finally, during the exhaust stroke, the exhaust valve opens, allowing the spent gases from combustion to exit the cylinder as the piston moves back upward. This expulsion of gases is critical for maintaining engine function, ensuring that the remaining air-fuel mixture can ignite without hindrance in subsequent cycles. Understanding these four steps is vital for anyone interested in the workings of engines and the broader automotive field, emphasizing the remarkable engineering behind cars.

Fuel and Air Mixture: The Heart of Combustion

The fuel and air mixture is crucial in understanding how a car engine works, as it directly influences engine performance and efficiency. In an internal combustion engine, optimal combustion relies on the right balance of fuel and air. An improper mixture can lead to power loss, increased emissions, and potential engine damage. Therefore, engineers place significant emphasis on achieving the ideal fuel-to-air ratio.

To create the necessary fuel and air mixture, various methods are employed, the most common being the carburetor and fuel injection systems. The carburetor, which was widely used in older automotive designs, functions by utilizing a vacuum created by the engine’s inlet pressure to draw fuel from the fuel reservoir. This process allows the fuel to mix with incoming air before it enters the combustion chamber. However, modern vehicles typically rely on fuel injectors, which deliver a precise amount of fuel directly into the intake manifold or directly into the combustion chamber. This system offers greater accuracy, responsiveness, and efficiency, enhancing overall vehicle performance.

The importance of achieving the correct fuel-to-air ratio cannot be overstated. For most gasoline engines, a ratio of approximately 14.7 parts air to 1 part fuel is considered ideal, allowing for complete combustion. When this balance is maintained, the engine operates efficiently, producing maximum power while minimizing harmful emissions. Conversely, a mixture that is too rich (excess fuel) or too lean (excess air) can lead to suboptimal performance, increased consumption of fuel, and potential long-term damage to the engine components.

In essence, understanding how a car engine works extends beyond the mechanical elements to include the intricacies of the fuel and air mixture. This fundamental process is what powers the vehicle and contributes to its operational effectiveness, influencing everything from acceleration to environmental impact.

Ignition and Combustion Process

The ignition and combustion process is central to understanding how a car engine works effectively. At the heart of this process lies the ignition system, primarily responsible for igniting the air-fuel mixture within the engine’s cylinders. The spark plug plays a critical role in this mechanism. When the engine is powered on, the ignition coil generates a high-voltage electric current that travels to the spark plug. This current creates a spark in the combustion chamber, where the compressed air-fuel mixture awaits ignition.

Once the spark ignites the air-fuel mixture, combustion occurs. This rapid chemical reaction releases energy in the form of heat and expanding gases. The pressure generated by this explosion forces the engine’s pistons downward, which is converted into mechanical energy. The movement of the pistons is a crucial aspect of how car engines generate propulsion. A series of controlled explosions and the timely firing of spark plugs are vital; they ensure that the power stroke occurs at the right moment to optimize engine performance.

The combustion process is not only about creating energy; it also involves the efficient removal of exhaust gases produced after the fuel burns. The combustion chamber includes intake and exhaust valves that open and close in a coordinated manner to allow fresh air to enter and spent gases to exit. This cycle continues with remarkable precision, typically following a four-stroke cycle of intake, compression, power, and exhaust. Understanding this cycle gives insight into the intricate workings of automotive engines and how they are finely tuned to achieve maximum efficiency and power output while minimizing harmful emissions.

Engine Cooling and Lubrication Systems

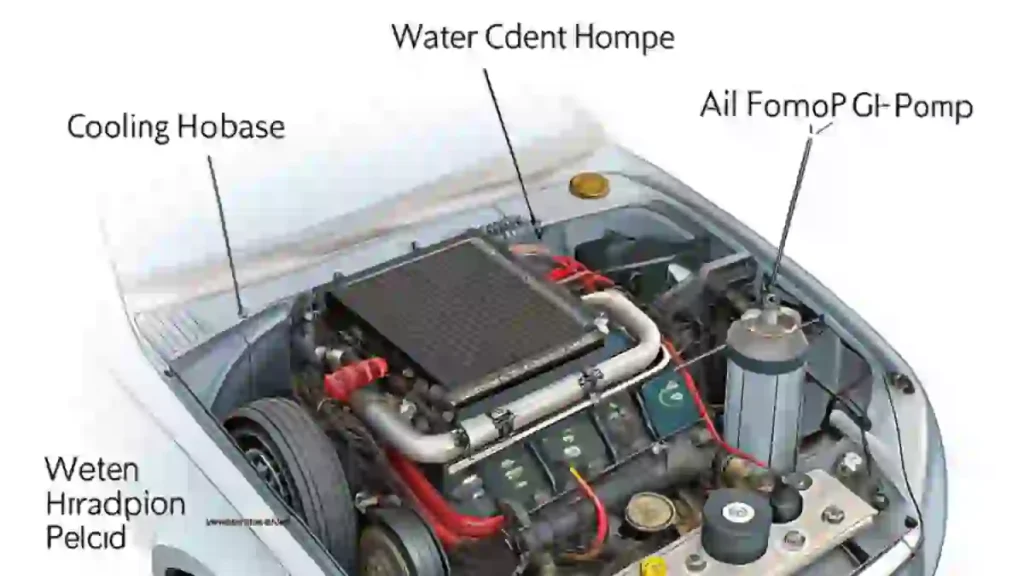

Understanding how a car engine works requires a closer look at the critical systems that ensure its reliable operation, including the engine cooling and lubrication systems. These systems are essential for maintaining optimal engine temperature and reducing friction between moving parts, which ultimately enhances the performance and longevity of the engine.

The cooling system primarily utilizes a coolant, which circulates through the engine to absorb excess heat generated during combustion. This process is crucial because an overheating engine can lead to significant damage. The coolant is typically a mixture of water and antifreeze, which not only helps in regulating temperature but also prevents corrosion within the engine. As the coolant absorbs heat, it is pumped to the radiator, where it dissipates heat into the atmosphere before returning to the engine. This continuous cycle is essential to keep the engine operating within a safe temperature range.

In addition to cooling, the lubrication system plays a vital role in minimizing friction among the engine’s moving parts. The oil pump is at the heart of this system. It ensures that oil circulates throughout the engine, reducing wear and preventing overheating caused by friction. Lubricants, typically petroleum-based or synthetic oils, create a protective film over engine parts, allowing them to move smoothly relative to one another. Different types of lubricants are available, each formulated to meet specific engine requirements, ensuring that the engine runs efficiently under various conditions.

In conclusion, grasping how a car engine works necessitates an understanding of both cooling and lubrication systems. These systems work in tandem to regulate temperature and reduce friction, thereby enhancing overall engine performance and longevity. By maintaining these systems, car owners can ensure their vehicles remain reliable and efficient throughout their operational life.

Engine Performance Factors

The performance of a car engine is influenced by a variety of factors, each contributing to the overall efficiency and output of the automotive machine. One of the primary determinants is engine size, often referred to as displacement. This measurement indicates the total volume of all cylinders in the engine, which plays a crucial role in determining how much air and fuel can be burned. Generally, a larger engine displacement allows for more power generation, leading to increased horsepower and torque. However, this can also impact fuel efficiency, as bigger engines typically consume more fuel.

Horsepower and torque are essential metrics that define an engine’s capability. Horsepower represents the engine’s ability to do work over time, while torque measures the rotational force available at the engine’s output shaft. Both elements are pivotal when evaluating how a car engine works; their relationship significantly impacts vehicle acceleration and performance. For instance, a high-torque engine can provide quicker acceleration from a standstill, which is particularly advantageous in scenarios like towing or carrying heavy loads.

Furthermore, modifications can play a significant role in enhancing engine performance. Upgrades such as a cold air intake, performance exhaust systems, or engine tuning can lead to better airflow and improved combustion, thereby maximizing both horsepower and torque. However, it is essential to balance these alterations with their implications for fuel efficiency, emissions standards, and overall vehicle longevity.

Finally, regular maintenance is critical for ensuring optimal engine efficiency. Routine checks, including oil changes, filter replacements, and spark plug inspections, help in maintaining performance by preventing the build-up of debris and ensuring that all components function effectively. Neglecting these maintenance tasks can lead to a decrease in performance and efficiency, ultimately impacting how a car engine works over its lifespan.

Common Engine Problems and Diagnostics

Understanding how a car engine works is essential for any vehicle owner, as it facilitates better comprehension of potential issues that may arise. Common engine problems can significantly impact automotive performance, making timely diagnostics crucial for maintaining efficiency. One prevalent issue is engine noise, which may manifest as knocking, tapping, or grinding sounds. These noises can be indicative of various problems, such as low oil levels, worn bearings, or damaged components. Carefully listening to the engine’s sounds during operation can provide valuable clues for diagnostics.

Another frequent engine-related problem is overheating, which can lead to severe engine damage if not addressed promptly. Overheating may stem from a malfunctioning thermostat, a damaged water pump, or a coolant leak. Monitoring the temperature gauge on the vehicle’s dashboard is essential to catch signs of overheating early. If the gauge shows unusually high readings, it is advisable to pull over and allow the engine to cool down before investigating the cause further.

Reduced power is also a common issue experienced by drivers, which can result from various concerns, including air intake obstructions, fuel delivery problems, or issues with the ignition system. A noticeable drop in performance when accelerating can be a signal that something in the engine is amiss. Regularly maintaining the car, such as replacing air filters and spark plugs, can mitigate some of these concerns.

For effective problem resolution, utilizing diagnostic tools such as an OBD-II scanner can provide insights into potential engine malfunctions by reading error codes stored within the vehicle’s computer system. This technology allows for streamlined troubleshooting and informed decision-making regarding necessary repairs. By understanding common engine problems and employing appropriate diagnostic techniques, vehicle owners can ensure their automotive engines function optimally and remain reliable over time.

Future of Engine Technology

The automotive industry is undergoing a significant transformation as it embraces the future of engine technology. With growing concerns over climate change and sustainability, there is an evident shift from traditional internal combustion engines to electric and hybrid variants. This transition signifies a notable move towards reducing carbon emissions, thereby addressing environmental issues while maintaining high performance. Electric vehicles (EVs) and hybrid vehicles are gaining market share, leading to advancements in battery technology and energy efficiency.

As electric powertrains become more prevalent, manufacturers are investing in smart materials and lightweight designs to enhance the overall efficiency of vehicles. This represents a critical aspect of how a car engine works in the future, as efficiency will not only improve fuel economy for hybrid vehicles but also significantly extend the range of fully electric cars. Innovations in regenerative braking and energy storage further bolster this trend, allowing engines to harness energy that would otherwise be wasted.

Another noteworthy trend in the evolution of engine technology is the integration of artificial intelligence (AI) in engine management systems. AI facilitates real-time data analysis, enabling systems to optimize performance based on driving conditions, fuel efficiency, and emissions. Such advancements provide insights into how a car engine works, allowing for proactive maintenance and improved overall function. The application of machine learning algorithms also enhances predictive capabilities in engine diagnostics, potentially reducing costs and downtime for automotive owners.

Engine Efficiency In conclusion, the future of car engine technology is poised for groundbreaking changes driven by electric engines, advanced efficiency measures, and smart, AI-powered systems. These developments promise to revolutionize the automotive landscape, leading to cleaner, more efficient, and technologically advanced vehicles. Understanding these shifts is crucial for consumers and industry professionals alike as they adapt to this evolving era in the automotive sector.